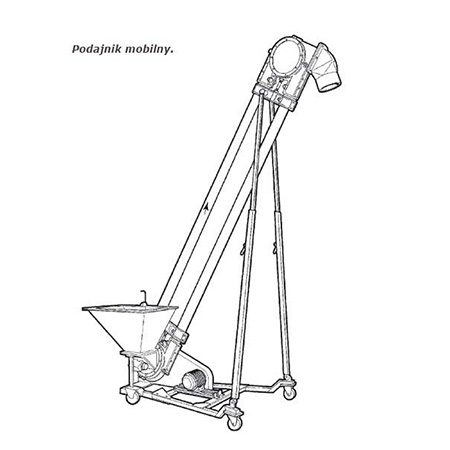

Aero Mechanical Conveyor (disc-in-tube conveying technology)

Applications:

- disc-based conveying of powders and granular materials (minimal damage to friable or sensitive products),

- products commonly handled by AMCs: potato crisps, coffee, tea, suggar, spices, milk powder, animal food, frozen foods, sodium, calcium, fluorine, aluminium, PVC, etc.,

- industries: building products, chemical, cosmetics, food, etc.

0

Categories: Conveying Systems, POWDER PROCESSING AND HANDLING

Specifications:

- entirely enclosed design suitable to convey the following products:

- harmful to human health,

- irritating,

- hygroscopic,

- easily oxidized,

- sterile,

- no need for dust collection,

- product is not damaged or separated,

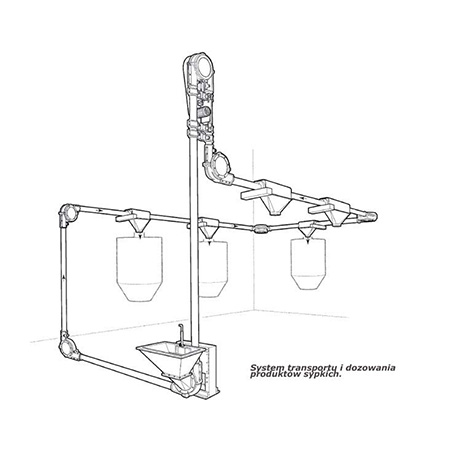

- infitite variability of system layout (unrestricted number of bends at any angle, inlet position, the location and number of distribution points),

- highly energy-efficient,

- effective conveying,

- available in various materials to suit the properties of products to be conveyed, such as abrasiveness or corosive properties,

- a wide range of accessories and optional extras are available.

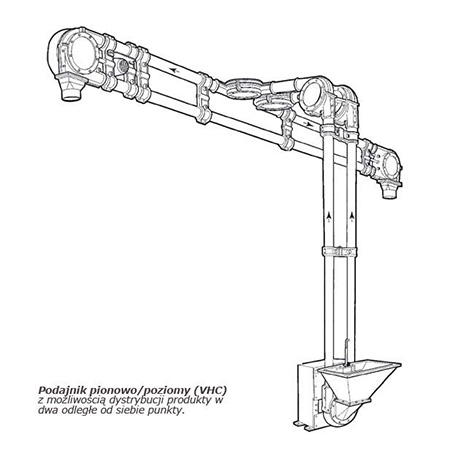

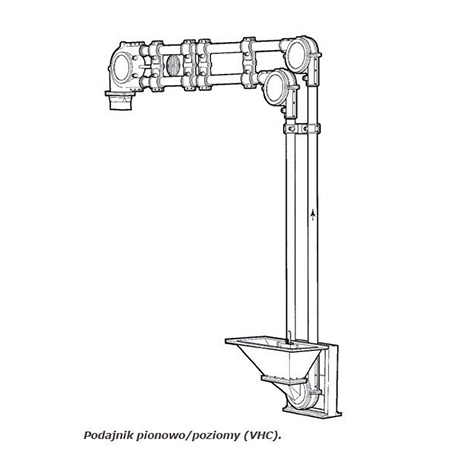

VHC – Vertical/Horizontal Conveyors:

- two remote vessels can be charged from a single feed hopper in low headroom conditions,

- material transfer rate up to 30 m3/h.

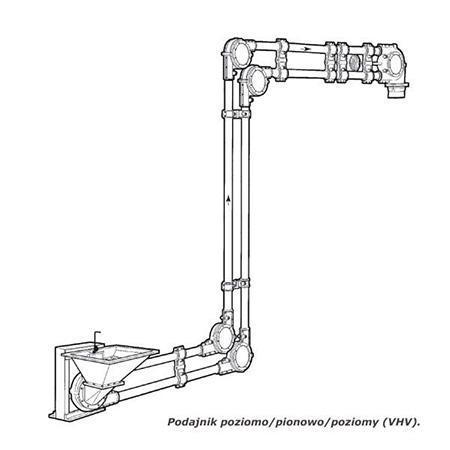

HVH – Horizontal Vertical Horizontal Conveyors:

- one or multiple infeed stations can be used,

- material transfer rate up to 30 m3/h.

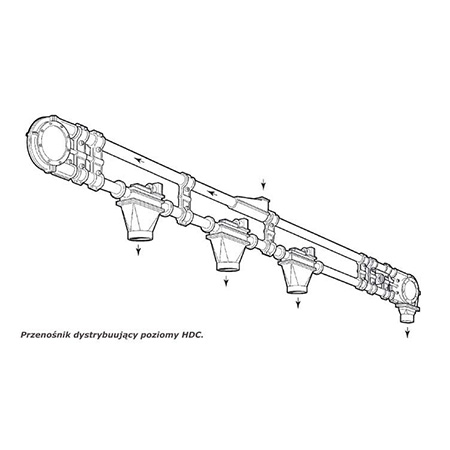

HDC – Horizontal Distribution Conveyors

- distribution of material to multiple outlets,

- material transfer rate up to 15 m3/h.

Rotopurge Cleaning System:

- effective cleaning both during or after a production batch by presurised clean dry air injected into the conveyor end assemblies.