Powder processing and handling

Pneumatic Conveyance

Aero Mechanical Conveyor (disc-in-tube conveying technology)

Big-Bag Filling and Discharge Systems

The big-bag systems we offer allow efficient filling/discharge of flexible intermediate bulk containers (FIBCs or big bags) with minimal operator intervention. Some of the basic features include ability to work with bags of various heights, ATEX certification for use in areas where explosive atmospheres may occur, dust-free operation and a built-in weighing system. Other special features may be included at the customer’s request.

Unloading of big-bags

Loading of big-bags

SamFreeglide Inline Sampler for Powders and Granules from Downpipes

SamFlow (ball valve for sampling)

HP Cross Belt Hammer Sampler

FP Chute Sampler

CBBS Type Cross Belt Bucket Sampler

Valves

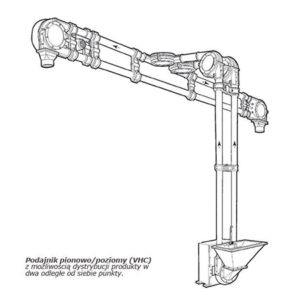

Rotary feeders also known as rotary airlocks or rotary valves – used for discharge of bulk solid material from silos, air filters and cyclones to create a constant flow of powders and granulates in dosing and pneumatic conveying systems. They are ATEX certified and can be installed in explosion risk zones as well as being used as certified explosion isolation devices.

Butterfly valves ‒ commonly used for isolating and sometimes for regulating flow in pneumatic conveying lines and gravity conveyors.

Diverter valves ‒ used where it is necessary to divert the flow of product (one inlet, two or more outles). Typical applications include pneumatic or gravity conveyors.

Explosion Isolating Rotary Valve

Butterfly Valves

Diverter Valves

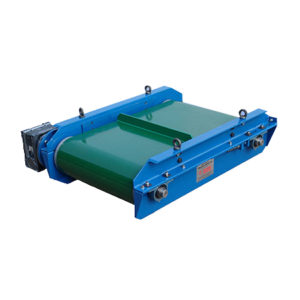

Magnetic Separators

Magnetic separators can be divided, according to their application, into two categories:

‘Primary’ separators are used to eliminate larger contaminant particles (typically including nails, screws, nuts, etc.) from bulk material in order to protect machines and equipment from damage and eliminate potential sources of ignition (fire and explosion protection).

The purpose of ‘secondary’ separators is to improve the quality of your product, removing smaller particles such as rust or metal filings. They are used to protect contamination sensitive process equipment or final product packaging lines (food, pharmaceutical or chemical industries).

Magnetic separators are also referred to as metal separators or industrial magnets.