Tri-Mode Technology:

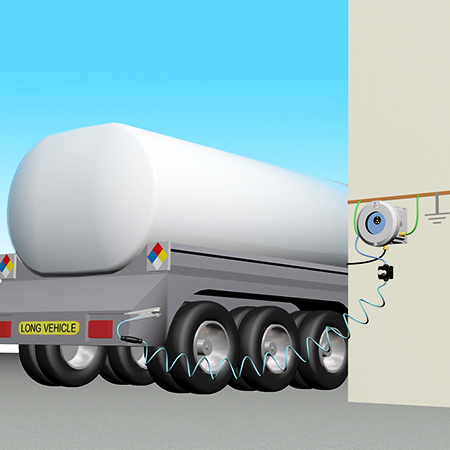

The Earth-Rite RTR is an advanced system for protecting personnel and plant assets from static hazards during tanker truck loading and unloading operations. It utilises a three-stage process:

- Road Tanker Recognition

This function is capable of differentiating connection to a road tanker, ensuring the system is not activated by:

• connection to parts of the truck not electrically continuous with the tank body, or

• connection to other metalwork like the loading gantry.

If the RTR clamp is not connected to a road tanker, the RTR system will not permit the transfer of cargo. - Ststic Ground Verification

The RTR verifies if it has a low resistance connection to True Earth via the structure to which it is connected, e.g. the loading rack.

If the RTR does not detect a high integrity ground connection, the system will not permit the transfer of cargo. - Continuous Ground Loop Monitoring

This function continuously monitors the full static dissipative loop from the tanker body to the ground connection during the transfer of hazardous cargo, ensuring resistance in the circuit never rises above 10 ohms.

If the resistance of the tank truck’s connection to the verified earth ground ever rises above 10 ohms, the RTR will go non-permissive.

Product Features:

- attention grabbing LED indicators (green/red) — pulsing green LEDs inform the personnel that the system is continuously monitoring the condition of the ground connection,

- two volt free contacts that can interface with control circuits for pumps, valves, PLCs, etc,

- wide operating temperature range: -40 to +55°C,

- detachable clamp & cable — the Quick Connect system provides flexible and easy removal of grounding clamp and cable from the hazardous area for maintenance,

- system components: monitoring unit, junction box/stowage point, grounding clamp, spiral cable,

- the monitoring unit enclosure is made in copper-free cast aluminium.

Options:

- ‘SoundEx’ audible alarm system for use when the transfer process cannot be interlocked,

- Mode Selector Key Switch — permits loading area supervisors to turn off the Road Tanker Recognition function of the RTR with a key when items of plant other than road tankers, e.g. railcars, IBCs and drums need to be filled or emptied,

- Self-Retracting Cable Reel,

- RTR System Tester — provides engineers with a means of checking that the RTR is functioning as expected when the road tanker is not present.